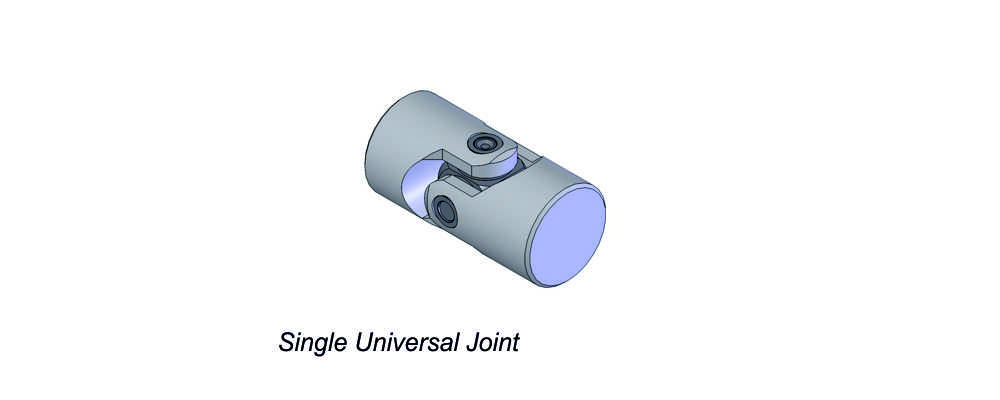

Single Universal Joints

Single universal joints can compensate an angular offset of up to 45° between the input and output shaft.

They typically operate at larger angles and higher torques than other types of couplings. They are also torsionally rigid and do not flex or wind up.

Single joints are subject to non-uniform speeds at input and output shafts. This means that when the speed at the input shaft is constant, the speed at the output shaft fluctuates.

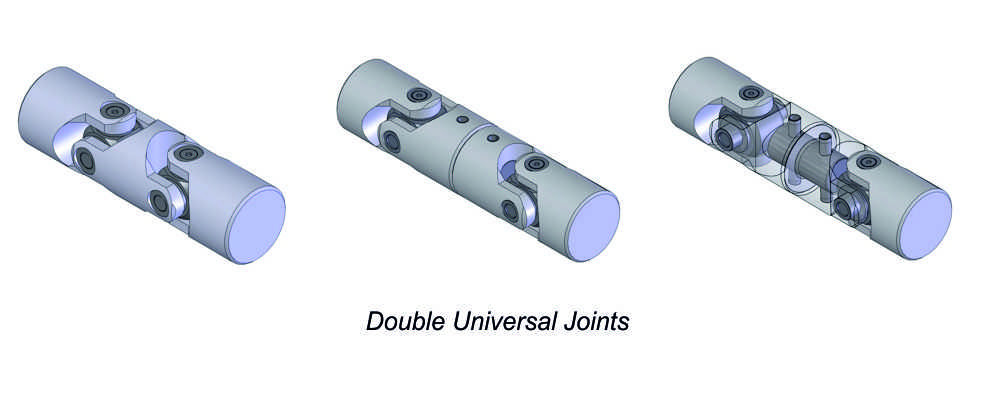

Double Universal Joints

Double Universal Joints can be created from two single joints by pinning or butting the hubs together, or specially designing the double joints with a single center section, to eliminate additional machining and assembling.

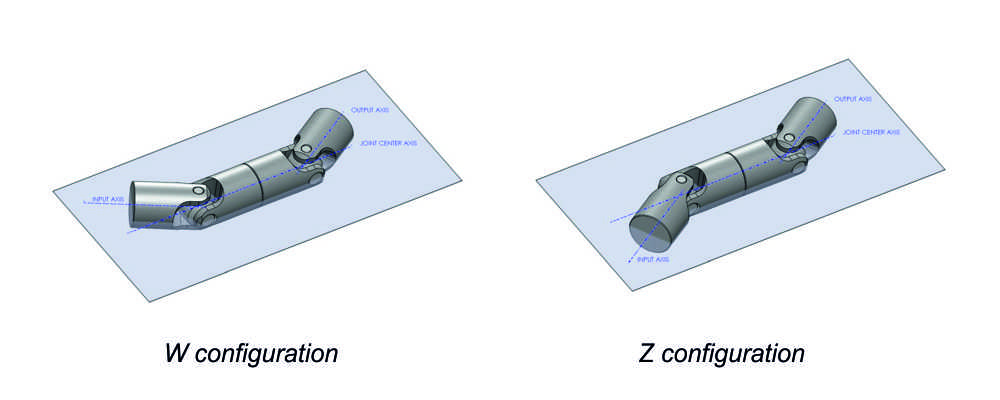

The advantage over a single joint is either an increased operating angle (W configuration) or the capacity to compensate parallel misalignment

(Z Configuration). They can also compensate the non-constant veloctiy between driving and driven shaft on a Single Universal Joint as long as they are oriented correctly.

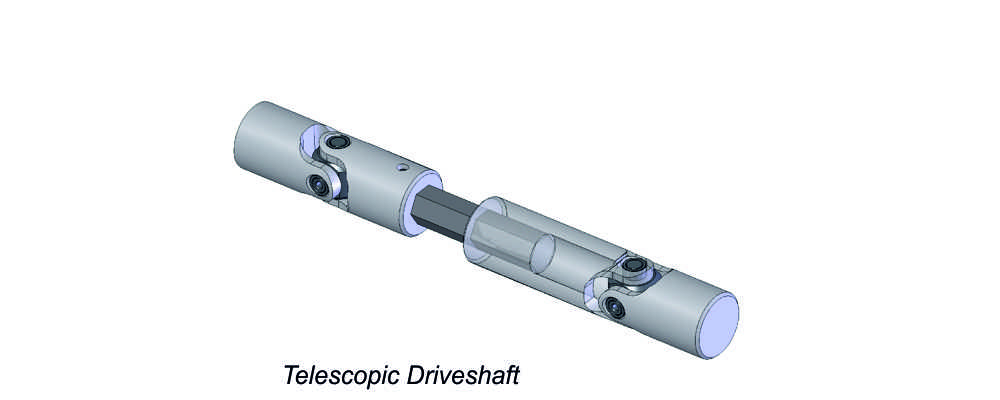

Telescopic Joints

Telescopic drive shafts or double cardan joints are essentially a double joint with a section in the center that allows a flexible length of the center piece. The adjustable center element of a double cardan joint allows the shaft's length to be varied for easy installation or to compensate for axial play. This type of shaft can be used wherever a drive and its output shaft have not only parallel and angular misalignment, but axial displacement as well. Anywhere the position of the motor (drive) or the load (output) is frequently changed, an articulated shaft with a telescopic segment allows quicker, simpler repositioning than possible with a rigid two-joint shaft.

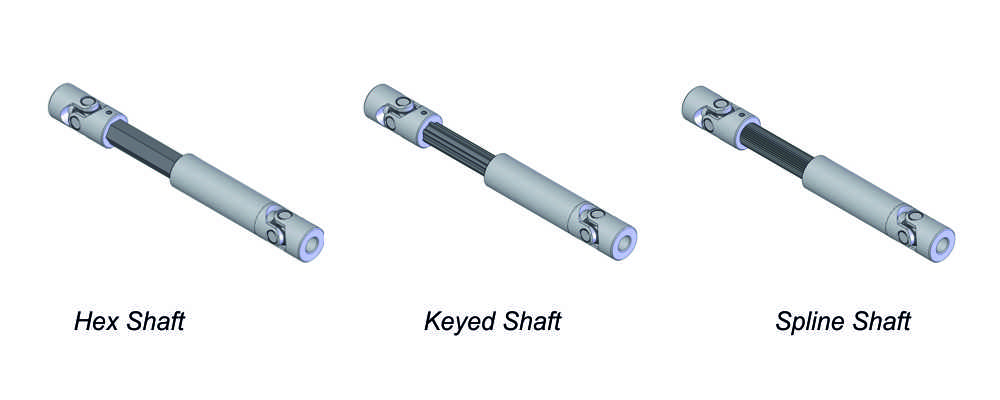

There are also applications that require a length change of the drive shaft in operation since one or both ends move. Depending on the application and environment, different profiles can be selected to design the center sliding feature. The simplest form is a square or hex shaft on one side with a mating hub on the other side. These connections are robust and cost-efficient.

For more precision and /or torque capacity, parallel-sided splines or shafts with multiple keys are a better option. Angled or involute spline profiles are available for extreme cases, but they come at a significantly higher cost.

Request Information For Single, Double, and Telescopic Joints

Wear on the shaft can be an issue when the sliding features move under load and during rotation – especially for stainless steels. Heat treatment or special coatings can be used to counter the negative effects.

In some cases, ball splines may offer a low friction and low wear option for long life.