Adaptability and Performance for High Torque Operations

As today's metal processing lines are becoming more versatile and efficient, components are required to operate in increasingly tight envelopes. Belden's machined universal joint and drive shaft solutions adapt to these dynamic requirements, while delivering maximum strength and reliability during the extreme torque of metal processing applications. Our machined universal joints frequently outperform generic forged u joints for small operating envelopes used in modern metal processing equipment.

Outperforms Competition

|

Leveler Strength Universal Joint |

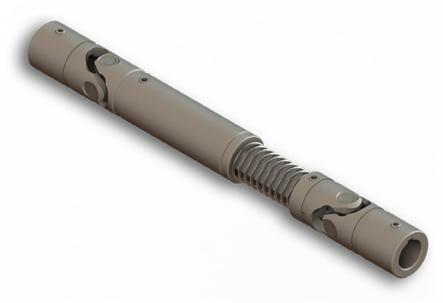

Unique, Spring-Loading Telescoping Drive Shaft, for Easy Installation

Overstressing Your Mill? Beware of the Weakest Link

Universal Joint Upgrades are Necessary for High Speed, High Torque Applications

As published in the Tube & Pipe Journal

Product Examples

Related Product Lines

Application Examples

- Leveling

- Roll Forming

- Straightening

- Coil Slitting

- Tube Mills

- Stamping