This pin & block (friction-bearing) drive shaft was constructed with high-strength design, accommodating high-torque applications and larger shaft diameters. It has a special, low-diameter sleeve, supporting an unusually long coilover spring, necessitated by the short overall length and amount of stroke and force involved. The hex-shaft is axially retained, to prevent disassembly at maximum length. The moving components are protected with lubricant retaining Nitrile boot covers.

Product Highlights

Used in a conveyor system, this 1.25” OD double universal joint with spline shafts was manufactured from high-grade alloy steel and zinc-plated for corrosion resistance. Apart from the splines, all exposed areas of the joint were spray-coated with ARDOX corrosion-inhibiting compound.

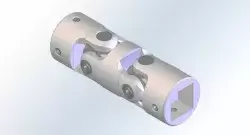

This 3.75” long, 1” diameter pin & block universal joint is machined from AISI 303 stainless steel yokes and 416L pins & blocks, for corrosion resistance in a pipeline application. The special pin-bores with milled seating areas for the pins are notably different from regular pin bores.

This 2.5” OD double universal joint features a short-coupled and very compact yoke profile, providing maximum possible strength to the design. With a 0.77-inch center section and an overall length of just 7.5 inches, it offers a great solution for applications where both strength and tight machine space are important considerations.

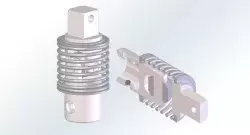

This booted telescopic drive shaft was developed for a testing application operating with significant axial movement during operation. It has been designed with a ball spline along the center of the shaft. The ball spline is well-suited for high-precision operations with continuous axial movement over pronounced distances, at significant speeds.

Belden has developed this custom universal joint for an exterior linkage application. Since the joint is exposed to outdoor elements, it is wholly manufactured from AISI303 stainless steel for corrosion resistance. Both hubs feature a threaded bore. The component was outfitted with an offset block for maximum angle and articulation.

This 1.25” single universal joint was developed from 7075-T651 grade aluminum, delivering a high strength-to-weight ratio. Needle bearings were required for reduced friction and backlash over extended periods of time. The right end was designed with a ‘cone-shaped’ hub connection and a keyway, in order to lock the joint in place.

The customer's previously used product often suffered from worn-out spline shafts since the application required the shaft to extend and compress in operation. The drive shaft was also lacking proper lubrication, since the application did not allow space for a lubricant retaining boot.

This telescopic drive shaft is almost entirely encased in nitrile boots. The yokes and other exposed components were manufactured from AISI 303 stainless steel. The clamp hubs with blind bores and keyways ensure easy installation.

This stainless steel universal joint with a 2-inch OD was custom designed for a remotely-operated valve actuation project. The female end of the joint is mounted on a Remotely Operated Vehicle (ROV), with the male end actuating the valve.