Robotic Joints: The precision you need to keep things in motion

Belden’s Needle Bearing Universal Joints can attain high angles and operate at a higher RPM than other u-joints, making them perfect for a variety of motion control and robotics applications. With near zero backlash and rigid axial stiffness for push & pull loads, the needle-bearing universal joint is manufactured to meet the highest industry standards for precision. Customization is Belden's specialty - hubs can be machined in alloy steel with a variety of platings, various grades of stainless steel, forgings and extruded aluminum for a high strength-to-weight ratio for robotic joints.

Typical Requirements

- High precision

- Minimal backlash

- High angles of articulation

- High RPM in continuous operation

- Special materials

- A veriety of sizes and configurations

Robotic U Joint Features:

Needle-Bearing u joints for |

Stainless steel and booted u joints |

PTFE or Xylon coating |

A variety of sizes and configurations including telescoping drive shafts |

Product Examples

Related Product Lines

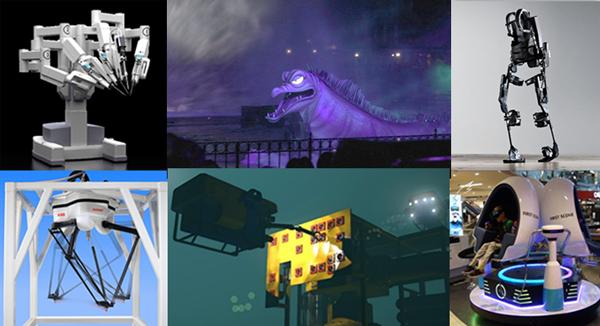

Application Examples

- Testing and probing

- Animatronics

- 3D motion platforms

- Antenna positioning