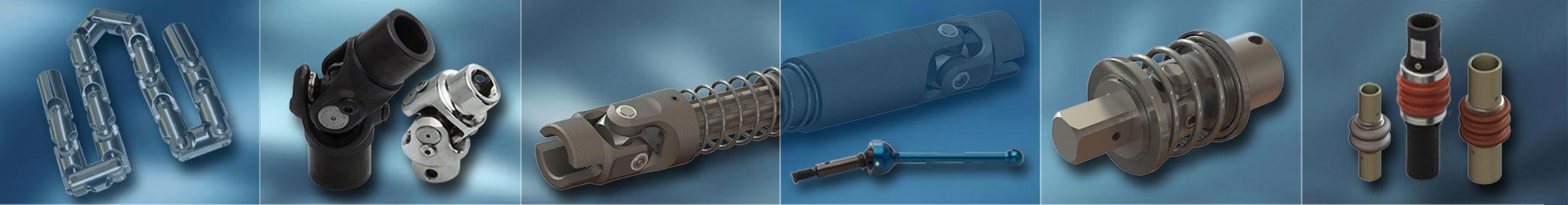

Universal Joint: A mechanical device that can transmit torque and/or rotary motion from one shaft to another at fixed or varying angles of intersection of the shaft's axis. Other terms also used are U-Joint, UV Joint or Cardan Joint.

Heavy Duty Universal Joint: Consists of large hole yoke and small hole yoke, pin and block style. A higher grade of steel is used in manufacturing the joint, making it a better choice over.

High Strength Universal Joint: Consists of two large hole yokes, pin and block design with bushings rather than the traditional snap ring. The peened pin rivet that holds the components into place makes it a stronger joint than the Heavy Duty Joint. The High Strength Joint is great for applications that require operating at a higher torque. The joint is also designed to accommodated larger shaft diameters.

Leveler Strength Universal Joint: Has an expanded torque capacity due to the profile, material up grade and manufacturing process. The basic function of the universal joint remains the same but the mechanical properties are enhanced, extending the operating life of the universal joint.

Needle Bearing Universal Joint: Needle bearings are installed at the pin ends to reduce backlash and increase precision and RPM capability.. The Needle Bearing Joint is a sealed/lubricated cross & bearing style available with or without boots. The joint has rigid axial stiffness of push/pull loads and can handle higher angles and rpm than other joints.

Double Universal Joint: Provides the same reliability and service life as the Belden Single Universal Joint but a maximum working angle of up to 90 degrees. Double Universal Joints provide accurate positioning and flexible action under difficult operating angles.

Telescopic Drive Shaft: A Double Universal joint with a length adjustable center section. Often also referred to as drive shaft or cardan shaft.

Pin and Block Friction Universal Joint: Also known as the Cardan Joint or Hooke's Joint, the pin and block is the simplest unit available. It allows for more positive transmission of rotating power or torque than conventional flexible couplings.

Cross and Bearing Needle Bearing Universal Joint: A forged cross with a needle bearing connection provides minimal backlash and precise positioning without compromising torque capacity.

Axial, Parallel & Angular Misalignment: Axial misalignment is the amount of axial movement (end play) between the shafts, which is typically caused by motor vibration. Parallel misalignment is the offset between driving and driven shaft. Angular misalignment is the angle at which the shafts intersect.

Zero Backlash: Zero backlash refers to the amount of torsional play within a coupling or universal joint assembly.

Duty Cycle: The load on a universal joint is either intermittent or continuous. Under most operating conditions, a joint's intermittent load capacity is greater than its continuous load capacity.

Constant Velocity: In order to achieve constant velocity operation, driving & driven shafts are required to be aligned parallel.

Yoke Orientation: When creating a double joint by connecting two single joints with a shaft, the yokes of the inbound joints are required to be aligned which is also referred to as phasing.

Torque: Torque is the force that causes rotation. Operating torque is the amount of torque that is transmitted during normal operation. Torque is commonly expressed in pound inches (lbf-in), pound-feet (lbf-ft), or Newton-meters (Nm).

Torsional Stiffness: Torsional stiffness is the degree of resistance against twist. It is commonly expressed in pound-inch/radian (lb in/rad) or Newton-meter/radian (Nm/rad).