Raising the Standard

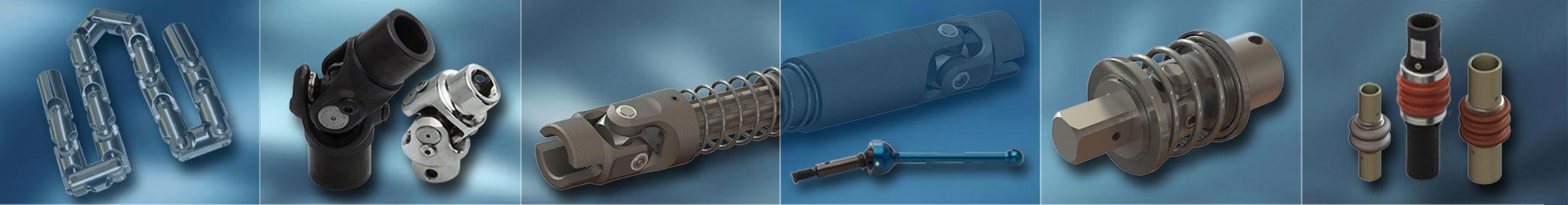

Most of Belden’s standard heavy duty alloy yokes are manufactured from AISI 1144 alloy steel, selectively hardened. Other materials may be used depending on size and/or series. Standard heavy duty alloy blocks and pins are typically manufactured from hardened AISI 8620 alloy steel for increased strength, durability, and better performance than other industrial-grade models. Standard stainless steel yokes are manufactured from Type 303 stainless steel; blocks and pins from hardened Type 416 stainless to prevent premature galling and wear and for increased strength, durability, and better performance than other industrial-grade models. Other materials available upon request. All components are manufactured to close tolerances and selectively heat treated where applicable.

Most of Belden’s standard heavy duty alloy yokes are manufactured from AISI 1144 alloy steel, selectively hardened. Other materials may be used depending on size and/or series. Standard heavy duty alloy blocks and pins are typically manufactured from hardened AISI 8620 alloy steel for increased strength, durability, and better performance than other industrial-grade models. Standard stainless steel yokes are manufactured from Type 303 stainless steel; blocks and pins from hardened Type 416 stainless to prevent premature galling and wear and for increased strength, durability, and better performance than other industrial-grade models. Other materials available upon request. All components are manufactured to close tolerances and selectively heat treated where applicable.

Special Materials for Unique Applications

In some instances, the use of a highly specific material may be prescribed, even if a technically suitable substitute is readily available. Locating rare or hard-to-source materials can pose a significant challenge. This can be the case, for example, in reverse engineering where part qualification and acceptance can depend on using the same exact material as the original part.

Belden uses a wide selection of materials for custom solutions - delivering increased strength, improved wear, corrosion resistance and other qualities:

- AISI 303, 304, 316L, 416, 420, 17-4, 15-5 Stainless Steel;

- Aluminum, Bronze & Brass Alloys;

- Suplex Stainless Steel (e.g. S32760);

- Super Alloys such as Inconel;

- Titanium and others.

Click to read more on specialty stainless steel selection for universal joints.

Titanium not only offers the highest strength-to-weight ratio among metals but corrosion resistance as well. Due to these qualities, depending on size and functionality requirements, this material is often suitable for special applications.

Titanium not only offers the highest strength-to-weight ratio among metals but corrosion resistance as well. Due to these qualities, depending on size and functionality requirements, this material is often suitable for special applications.

Aluminum delivers a high strength-to-weight ratio, but its bearing and wear characteristics are less favorable. Design concepts such as bushings can be a way around this.

Bronze and certain brass alloys also offer corrosion resistance and can be used as bushing material.

Nitrogen strengthened materials (e.g. Nitronic 60) provide vastly increased galling resistance over regular austenitic stainless steel and are sometimes considered for pins and blocks in applications where typical lubrication methods are not an option.