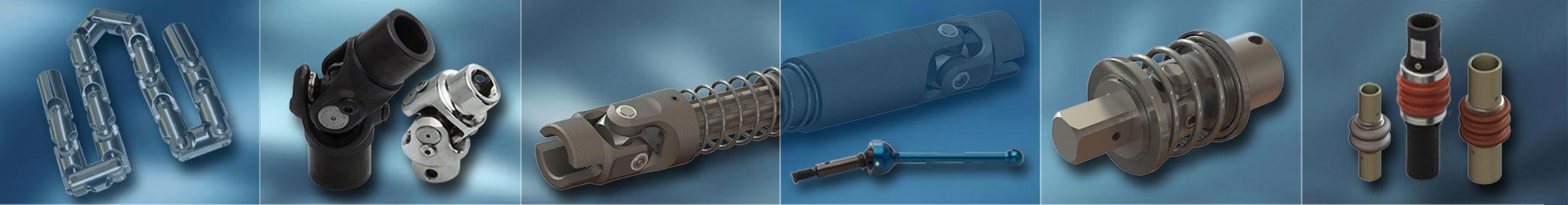

Belden Universal specializes in manufacturing high-precision standard and custom universal joints (also called cardan joints) for challenging applications. We can develop a wide variety of other machined components from bar stock, with complex geometries and outside diameters of 0.11” [2.8mm] to 8.0” [203mm]. Our responsive, award-winning design and production team delivers innovative engineered solutions for virtually any customer requirement.

TECHNOLOGYBelden Universal places heavy emphasis on investing in the latest production technologies. Our shop is outfitted with the latest in CNC Turning, Milling, and Grinding equipment, along with various specialized automation equipment selected for maximum efficiency. We can utilize our automated production cells on higher volume projects to achieve cost-savings for our customers. Our in-house testing and state-of-the art manufacturing equipment ensure that the end products meet our customers' highest expectations. | ||||

Production Equipment | ||||

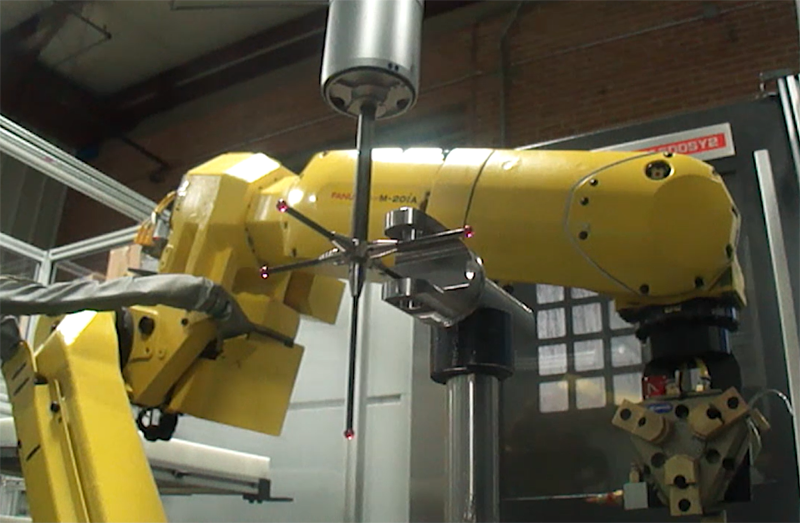

Multi-Axis CNC Machining Centers

Closed-Loop Manufacturing Cell

Automated Riveting Process

|  Closed-Loop Manufacturing Cell | |||

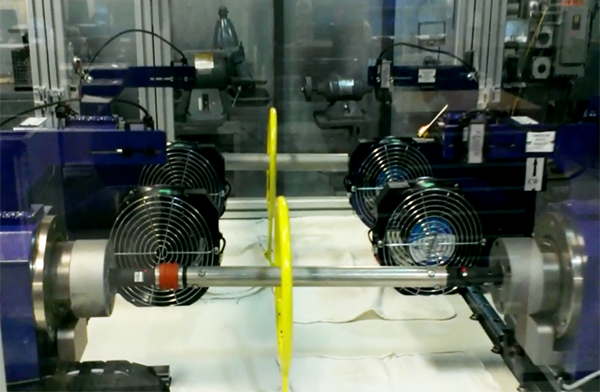

Testing & Inspection | ||||

In-House Testing Equipment

Digitized Inspection Records

Automated Measuring Equipment

|

| |||

Quality & Compliance | ||||

Broad Selection of Materials | ||

Component Materials

| Coatings & Platings

| |