How To Install U Joints

The instructions below show how to remove and install different types of Belden universal joints: Pin & Block Universal joints and u joints that require the peening of the small-diameter pin. Each process is similar with only minor differences in procedure. Here are the steps needed for installing universal joints.

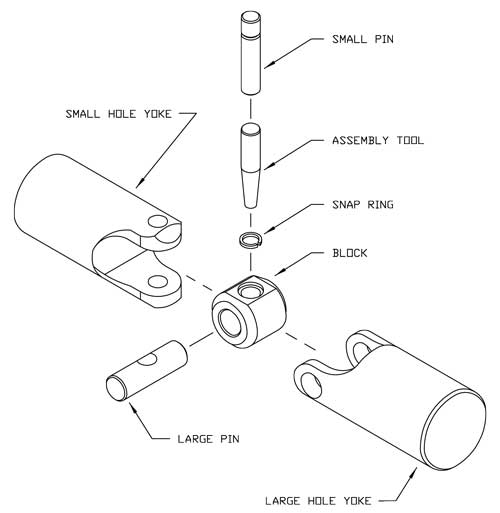

Instructions for Assembling a Belden Pin and Block Universal Joint

Tip: To ease assembly, use a v-block with a hole drilled into the bottom to enable the assembly tool to pass through it.

Step 1. Thoroughly clean all components.

Step 3. Disassemble the universal joint.

Step 4. Lightly grease all bearing and/or contact surfaces.

Step 5. Install the large-diameter pin through one hole in the large-hole yoke. With the large cross-hole of the block in line, push the large pin through the block and into the other hole of the large-hole yoke.

Step 6. Place the snap ring into the counter bore of the block and position the small-hole yoke on center of counterbored cross-hole.

Step 7. Insert assembly tool into small hole yoke and use the small pin to lightly drive the assembly tool through the universal joint. Note, be certain to correctly orient the groove in the small pin to coincide with the location of the snap ring in the block.

Step 8. Check for proper engagement of the snap-ring groove of the small pin by tapping on the small pin with a drive-pin punch and hammer.

Interested In Our Universal Joints?

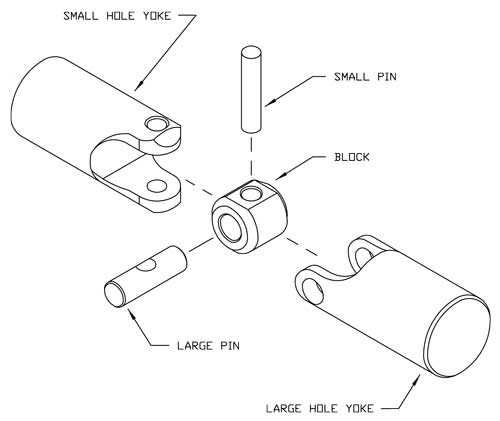

Instructions for Assembling Belden Universal Joints that Require Peening of the Small-Diameter Pin

Step 1. Thoroughly clean all components.

Step 2. Pre-assemble the universal joint without grease to verify correct movement of the universal joint (i.e. the motion should be smooth.)

Step 3. Disassemble the universal joint.

Step 4. Lightly grease all bearing and/or contact surfaces.

Step 5. Install the large-diameter pin through one hole in the large-hole yoke. Then with the large cross-hole of the block in line, push the large pin through the block and into the opposite hole of the large-hole yoke.

Step 6. Install the small diameter pin through the small-hole yoke, block, and large pin.

Step 7. Place the assembled universal joint on a flat, hard surface and peen the end of the small pin over equally from both sides with a ball peen-hammer. Use care so as not to crush the yoke or over-peen the pin.

Step 8. Check the assembly for correct movement.

Note: The small-diameter pin should not have any side-to-side movement.