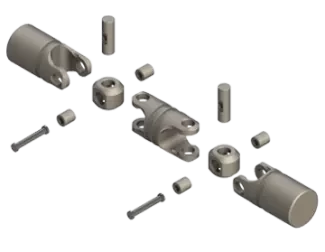

Belden's High Strength double universal Joints are recommended for high-torque applications (e.g. drilling, tapping, packaging, test cells and others.) They are constructed with friction-bearing (i.e. plain-bearing) design and are stronger than Heavy Duty joints. The high-strength double universal joints deliver minimal play, accurate positioning and flexibility under high operating angles. With a maximum combined working angle of 90° (45° per joint), they provide uniform speed-ratio between driving and driven shafts (with parallel output shafts).

Features:

- Outside Diameter: 0.37" - 4.00" [9.4mm - 100mm]

- Operating Torque: 23-20,000 Lb-In [2.7-2,237 N-m]

- Breaking Torque: 158-99,000 Lb-In [18-11,186 N-m]

- Operating speed: up to 1000 RPM (depending on lubrication)

- Operating Angle: up to 90° (45° per joint); special solutions with higher angles may be available

- Minimal play

- Material for yokes: high-grade alloy steel, hardened, precision honed & ground

- Material for pins & blocks: alloy steel, hardened and precision ground

- Regular re-lubrication required or joint can be fitted with grease-packed boots

- Boot grooves are standard (parts without grooves available upon request)

- Bores & keyways optional

- Hub ends available with several standard bore configurations (plain bore, keyway, hex and square bore)

- Optionally available plating: Zink, Nickel, Cadmium, MoS2, Black Oxide