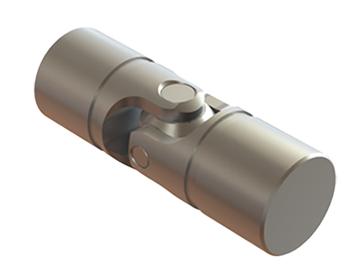

Food & Packaging Industry Universal Joint

DESIGNING TO WITHSTAND FREQUENT CLEANING AND STERILIZATION

A customer was having a problem with a standard cross and needle bearing universal joint during the wash-down phase on the automation equipment of his food application. The needle bearing joint would absorb the chemical solution used twice daily to clean and sterilize the equipment. Once the alloy bearings absorbed the chemical compounds, gumming would occur causing the joint to run tight, lock up and fail. After discussing operating conditions and product specifications with the customer, Belden Universal developed a precision engineered pin and block joint completely out of stainless steel with composite bushings, which provides a corrosion resistant, lubricant free, low friction plain bearing joint. The low friction pin and block plain bearing design enables a higher torque capacity of the friction bearing joint with the needle bearing's ability to continuously operate at higher speeds with less wear and even less backlash. The composite bearings can handle harsh abrasives found in the cleaning products used by the customer allowing the joint to operate freely and cycle for a longer duration before any precision is compromised. The Belden Universal solution provided the customer a completely wash-down safe universal joint, eliminating corrosion issues and contamination, burnout, and joint seizure.