Belden's unique 'hybrid' pin & block type needle-bearing design combines the higher torque capacity of friction-bearing (pin & block) joints with the needle-bearing’s ability to continuously operate at higher speeds with less wear, and lower backlash. It is better suited for high side-loads and operating angles than the cross & bearing style joints.

Features:

- Outside Diameter: 0.75"- 2.50" [19-50 mm]

- Operating Speed: up to 6000 RPM

- Operating Angle: up to 45°

- Near-zero backlash, low friction & wear

- Needle bearings lubricated for lifetime of the joint

- Yoke Material: high-grade alloy steel

- Material for Pins & Blocks: high-grade alloy steel, hardened and precision-ground

- Hub ends available with several standard bore configurations (plain bore, keyway, hex- and square bore)

Available as Double Joint and Telescoping Drive Shaft on request.

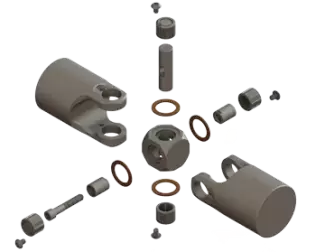

pin & block universal joint

exploded view of pin & block universal joint